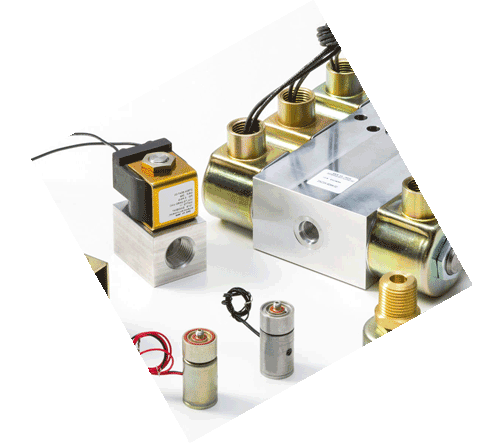

Made-to-Order Solenoid Valves

We design and build solenoid valves to our customer’s specific requirements. Known for our responsiveness, we offer complementary design & engineering services, fast prototypes, and US based manufacturing... all at OE direct pricing

GET STARTEDDon’t Settle for Stock Valves

We’ll design the most efficient valve solution for your specific application.

Super Responsive Service

Solenoid Solutions, Inc. is the most responsive solenoid valve manufacturer with a foundation of more than 50 years of experience and history in designing and manufacturing solenoid valves.

We invest heavily in our US based facilities with precision machining equipment, automated assembly centers, sophisticated quality assurance programs and advanced testing systems.

Technical Question or Problem Resolution

(often the same day)

The Competition

(maybe at a weekly meeting)

The Top 5 Reasons to Insist on Custom Solenoid Valves from Solenoid Solutions

We deliver superior quality solenoid valves, manifold systems and assemblies at OE Direct pricing.

Solenoid Valve Models

All of our solenoid valves are manufactured from the models listed below. Your valve is designed to meet your exact requirements and specifications. Review the models below, and then contact our sales/engineering team "directly" to begin.

High Capacity Valves

Frequently Asked Questions

Solenoid Solutions works exclusively with OEMs to provide high-quality solenoid valves and multi-valve manifolds in large volumes. We offer a range of purchasing and inventory programs like just-in-time delivery, inventory consignment, kan-ban, lean manufacturing practices, and more to drive cost out of the process and become a truly valued partner.

Solenoid Solutions is a USA-based manufacturer of made-to-order valves specific to our OEM customer’s requirements. We strive to be the most responsive valve manufacturer on the planet. We offer FREE engineering and design services, rapid prototyping, low part minimums, aggressive pricing, inventory programs, and after-sale support… we even make sales calls!

If you have a new project or looking to refine a current product that uses solenoid valves, you owe it to yourself to at least give us a try. What do you have to lose? Other than no engineering help, long development times, being pushed into an off-the-shelf valve and being treated like you’re a nuisance.

Call our sales team today.

The technical expertise and support capabilities of Solenoid Solutions, Inc. allow us to provide the most cost-effective flow control solutions for our customers. We design and build superior quality solenoid valve solutions for many industries, including medical, dental, food service, appliance, transportation, automobiles, and power generation industries. We supply electric solenoid valves to original equipment manufacturers (OEM industry) and to secondary markets.

Many manufacturing companies that are involved in industries such as hydraulic robotics for vehicle manufacturing and automatic plants use 2-way solenoid valves and other precision valves for flow control. These 2 and 3-way solenoid valves are used in a broad variety of industries such as in climate control and the paintball industry.

In industries where toxic gases are often used in production, the solenoid air valve allows a person to operate a valve without actually being close to the gas being transported.

Most applications require custom-designed and manufactured products. That is why our capabilities go far beyond the standard catalog offering. We offer many value-added benefits that, for our customers, improve efficiencies, reduce labor and save time and money.

Electrical control by means of 2-way solenoid valves is one of the most efficient methods of controlling liquid, gas, and pressure valves safely.

Most machinery that operates on hydraulics will use solenoid valve controls activated by switching equipment or electronic means. Using this type of control allows different switching positions rather than just a standard closed or open position, making a 2-way solenoid valve an ideal choice.

Solenoid Solutions offers a range of 2-way valves in different voltages for precision machine control. They can be controlled both manually and automatically and are used across a spectrum of industries worldwide.

Two-way solenoid valves allow for efficient controlling systems for any process and can easily be automated when coupled with computerized networks. They are used in many safety applications and shut-off mechanisms. Solenoid valve controls are extensively used in laboratories and in medical equipment where special control valves can mean the difference between life and death for patients.

Many manufacturing companies that are involved in industries such as hydraulic robotics for vehicle manufacturing and automatic plants use 2-way solenoid valves and other precision valves for flow control. For this reason, it is vital that only top-quality solenoids and valves are utilized because there is no room for error.

Using internet technology now provides you the convenience of choosing the equipment you need from 2 way solenoid valves from the biggest models right down to miniature valves for compact electronically controlled equipment.

Solenoids work much in the same way as a light switch - in the simplest construction, the presence of a current passing through a solenoid opens a valve, whereas the absence of a current closes it again. Solenoids can be found in anything from a paintball gun to a central heating system. Solenoid Solutions has been providing a broad spectrum of industries with reliable, quality solenoid products such as 2 and 3-way solenoid valves.

Electric solenoid valves are used in the regulation of fluids such as liquids and gases by passing or stopping an electrical charge through a solenoid. There are a variety of electric solenoid valves, the most frequent being 2 and 3-way solenoid valves. Two-way electric solenoid valves control the switching on and off of flow as pressure moves from one side to the other. Three-way electric solenoid valves involve switching the outflow between two outlet ports. Electric solenoid valves rely on a differential of pressure between input and output where pressure at the input must always be greater than pressure at the output in order for the system to function.

These 2 and 3-way solenoid valves are used in a broad variety of industries such as climate control, the paintball industry, and others where maintaining fluid control is necessary. A committed team of Solenoid Solutions' engineers paired with constant quality assurance and improvement of the manufacturing process ensures that this dynamic company continues to satisfy its customers with timely, reliable, and accurate solutions for their specific applications.

Electric solenoid valves find application in the control of fluids such as liquids and gases by running or stopping an electrical current through a solenoid. There are various types of electric solenoid valves; the most common being 2-way solenoid valves and 3-way solenoid valves. Two-way electric solenoid valves involve switching on and off the flow as pressure flows from one port to the other. Three-way electric solenoid valves involve switching the outflow between two outlet ports. Electric solenoid valves rely on a differential of pressure between input and output where pressure at the input must always be higher than pressure at the output for the system to work.

These valves find application in a wide range of industries such as in central heating, the paintball industry, and more where they are used to shut off, release, dose, distribute or mix fluids.

Pneumatic solenoid valves, flow control valves suitable for almost any application, can simplify the control of air in compressor machines and also automate the release of moisture for safety in airlines. A range of quality valves can be chosen to control a variety of other processes with precision.

Many manufacturing plants use air in their processes and the same goes for hospitals, laboratories, and machinery. Valves are a cost-effective and common method of lasting control for hydraulic equipment, pneumatic compressors and air lines, water and gas flow, and much more.

Industries are introducing the latest technology using pneumatic control valves and controls with electronic precision control that leaves little room for error. Valves are already used in many systems and applications across a vast sector of businesses and industries today. They are an integral part of safety in control while maximizing efficiency and speed.

Solenoid-operated valves rely on the exchange of fluids to manipulate the valve's state. They can be considered to be similar to a light switch; depending on the flow of the fluid, the valve can be either opened or closed. They are often used in pneumatic and hydraulic systems and can be found in an extensive array of products, from coffee machines to automobiles. While they may seem to be fairly simple constructions, it's critical to use high-quality valves to ensure reliability and predictability in operation.

Solenoid-operated valves are utilized in the regulation of substances such as gases and liquids by running or stopping an electrical current through a solenoid. There are a variety of electric solenoid valves, the most common being 2 and 3-way solenoid valves. Two-way electric solenoid valves relate to the switching on and off of flow as pressure moves from one side to the other. Three-way electric solenoid valves involve switching the movement between two outlet ports. Electric solenoid valves depend on a pressure difference between input and output where pressure at the input must always be greater than the pressure at the output for the system to work.

Solenoid valves are electrochemical valves used wherever fluid flow has to be controlled automatically, especially for the control of liquid or gas flow. There are a variety of designs suited to numerous applications in varied types of plants and equipment. Solenoid valves are control units that either shut off or allow the flow of fluid when electrically energized or de-energized. Solenoid valves are used for a number of tasks which include shutting off, releasing, dosing, distributing, or mixing fluids. Two-way solenoid valves have valves with one inlet and one outlet port while 3-way solenoid valves have three port connections and two valve seats.

In >2 way solenoid valves, pressure flows from one port to the other when power is applied, and when the pressure is off, fluid flow ceases. When the power is on in the case of 3-way solenoid valves, one of the ports is connected to the common port and pressure flows through to extend the pneumatic cylinder. When the power is off, the other port is connected to the common port and the pressure is exhausted to reset the cylinder. Solenoid valves find application in a wide variety of industries and on many occasions need to be customized for different needs.

Solenoids are used in a wide variety of products, from automobiles to paintball guns. While many are suited for multiple purposes, some tasks call for special-purpose solenoid valves to meet specific needs.

Electric solenoid valves are utilized in the management of fluids such as liquids and gases by passing or stopping an electrical charge through a solenoid. There are various kinds of electric solenoid valves, the most frequent being 2 way and 3-way solenoid valves. Two-way electric solenoid valves control the switching on and off of flow as pressure flows from one side to the other. Three-way electric solenoid valves involve switching the outflow between two outlet ports. Electric solenoid valves depend on a differential of pressure between input and output where the pressure at the input must always be more than the pressure at the output for the system to function.

See What Customers Are Saying

We are very proud of the service we provide and stand by every product we produce.

Read our testimonials from our happy customers.

I like that they design and machine their own componenets in the same U.S. facility as they design the product. They control the whole process. It is evident in the quality of their product.

Your team is focused on what we needed

Willing to listen - not just sell some finished valve

Very knowledgeable

Don't settle for valves, We offer

Complimentary Engineering Services!

Based here in the USA